Additive Manufacturing Technology

At Gleam Innovations, we design and develop parts of machinery and entire products using high-performance materials, such as PETG, Nylon, Carbon Fibre, TPU, PEEK, PEKK, & ULTEM 9085.

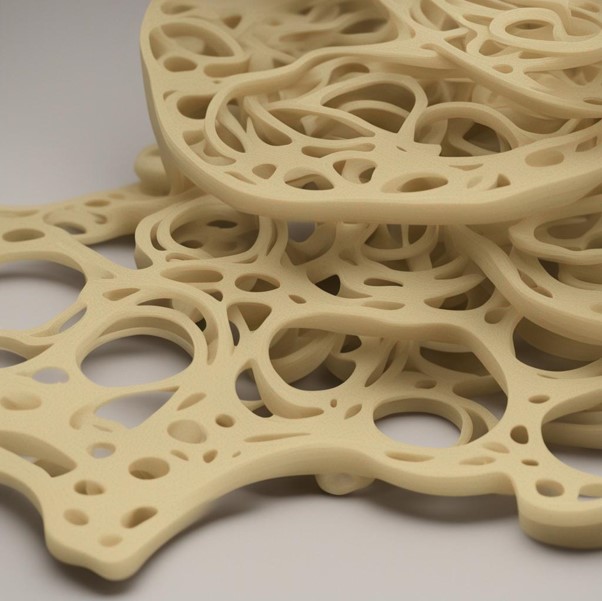

Our research and development focuses on leveraging high-performance materials, primarily TPU and ULTEM. We cater to various industrial applications by modelling and prototyping machinery, tools, and other products with exceptional features from these materials.

TPU exhibits high elasticity, warp resistance, chemical resistance, shock absorption, impact resistance, and other physical properties.

We design and prototype products of wide size and diverse, intricate structures for applications across several industries.

Chemically called polyetherimide, ULTEM is a semi-transparent, high-strength plastic material that can operate in high-service temperature environments. Its physical and thermal properties make it applicable in various industries.

We leverage its high strength-to-weight ratio to design, develop, and manufacture products for aerospace and automotive machinery and mechanical systems that have applications in industries like manufacturing.

Our Process Flow

Engineering Design

We produce precise 2D drawings and 3D models using advanced Computer-Aided Engineering Design (CAED) software like SolidWorks.

Material Selection

We select suitable materials that fulfil the products’ efficacy and application criteria.

Prototyping

We produce trial-ready prototypes using 3D printing technology to test the products and validate the designs.

Pilot Projects

We assist in small-scale production at low cost so that the client can market the functional prototypes and test their performance.

Upscaling

We facilitate the process development of large-scale production of the best of the prototypes.

The Advantages of our 3D-printing Technologies Provide

Precise Casting/Flawless

Replicable & Optimised Parameters

Tackle Intricate Structure

Minimal Wastage